A Biased View of Roar Solutions

A Biased View of Roar Solutions

Blog Article

10 Simple Techniques For Roar Solutions

Table of ContentsAbout Roar SolutionsRoar Solutions Fundamentals ExplainedThe Basic Principles Of Roar Solutions The 20-Second Trick For Roar Solutions

The devices register is a detailed data source of devices documents that includes a minimum set of fields to determine each product's area, technological criteria, Ex-spouse classification, age, and environmental information. The proportion of In-depth to Shut inspections will be established by the Tools Risk, which is examined based on ignition risk (the probability of a source of ignition versus the chance of a combustible atmosphere )and the unsafe location classification( Zone 0Area 1, or 2). Carrying out a robust Risk-Based Evaluation( RBI )method is essential for guaranteeing conformity and safety in handling Electrical Equipment in Hazardous Locations( EEHA).

With over one decade of mixed Ex lover experience (IECEx/ATEX, EEHA), Saipex began to promote the value of competence of all personnel included in the Hazardous Area area in 2019. In 2021, our partnership with IndEx and Technology Ability International (TSI) noted a milestone in the Saipex road to continue Ex enhancement.

Some Ideas on Roar Solutions You Need To Know

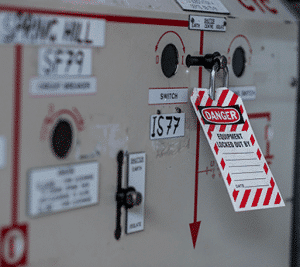

In terms of explosive risk, a harmful area is an environment in which an eruptive environment exists (or may be anticipated to be present) in amounts that call for unique preventative measures for the construction, setup and use tools. In this short article we discover the challenges encountered in the work environment, the risk control measures, and the required competencies to work securely.

(https://www.anobii.com/en/01749dcc41232b575a/profile/activity)

It is a repercussion of modern-day life that we manufacture, save or deal with a series of gases or fluids that are deemed flammable, and an array of dirts that are deemed flammable. electrical refresher course. These compounds can, in certain problems, develop explosive environments and these can have significant and heartbreaking effects. A lot of us know with the fire triangle eliminate any kind of one of the 3 aspects and the fire can not occur, yet what does this mean in the context of hazardous locations? When breaking this down right into its easiest terms it is essentially: a mix of a certain quantity of release or leakage of a specific substance or product, mixing with ambient oxygen, and the visibility of a source of ignition.

This is after that verified through assessment and testing and is preserved throughout the life of the setup by employing the appropriate maintenance strategies, supplemented by regular inspection. When all these actions are taken, they must likewise be documented. The verification dossier consists of info such as the dangerous area category drawing, suppliers' paperwork, tools certification, style illustrations and computations, evaluation documents, and records of a person's proficiency and proceeding expert development (CPD), such as using ECA's eCOMS software application.

The smart Trick of Roar Solutions That Nobody is Discussing

It is important that pupils recognize and have a thorough knowledge as to exactly what constitutes a harmful location. The trainee must additionally understand why training is necessary prior to trying to tackle work or defining equipment into a hazardous area. These locations are likewise called classified locations and are specified as locations which have a high probability of a surge due to the possible existence of flammable gases, vapors, dusts etc.

Industries that contain dangerous areas are now demanding that electric employees that are specifying or functioning in these locations ought to have a hazardous area certification that regards them skilled. Jobs in these industries are extremely gratifying so you need to be prepared. To meet this demand for the market, country wide recognised training in Certification IV in Harmful area Electrical and EEHA training on the growth of experienced experts.

Things about Roar Solutions

Tech Skills Australia is a Registered Training Organization supplying you with the most affordable and quickest way in acquiring your qualification - electrical refresher course. Our trainers are industry qualified and have several years of procedure experience. Our courses have helped thousands of people from company supervisors to daily staff members in obtaining a useful reference solid hang on this not so complicated but high risk training

The training likewise consists of identifying the harmful locations, sources of surge and the homes of dangerous products along with the responsibilities and features of all parties, regulations, systems, requirements and practice codes connected to unsafe areas. We offer instrumentation and unsafe location services that remain in compliance to newest AS/NZS and global sector standards.

Report this page